Hull Epoxy

To prevent the development of Osmosis, Audaciter was taken to a leading UK boatyard to have her hull professionally stripped, dried and epoxied.

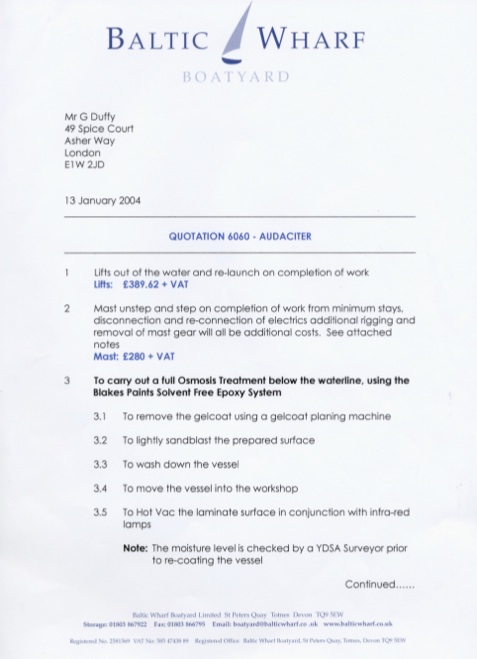

Audaciter was taken to Baltic Wharf Boatyard, at Totnes on the River Dart.

Baltic Wharf specialise in anti-osmosis treatment and their staff were both knowledgable and friendly. Their workshop manager came down to Dartmouth to help navigate the upper reaches of the Dart.

The gel coat was stripped off and the laminate then dried over several weeks using infra red lamps and hot vac (vacuum) moisture extraction pads.

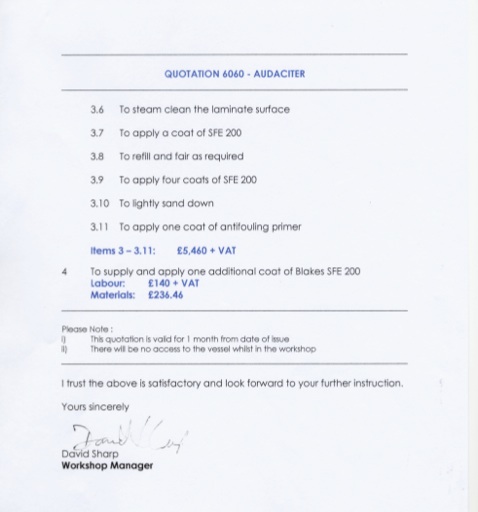

The moisture levels were monitored by a surveyor and when complete the hull was prepared and epoxied. An initial coat was applied, then filled and faired. The usual four further coats of epoxy were then applied. We also commissioned an additional fifth coat of epoxy for greater longevity of the protection.

With the mast stepped we took the opportunity to fit a new tricolour and all round white light to the mast.

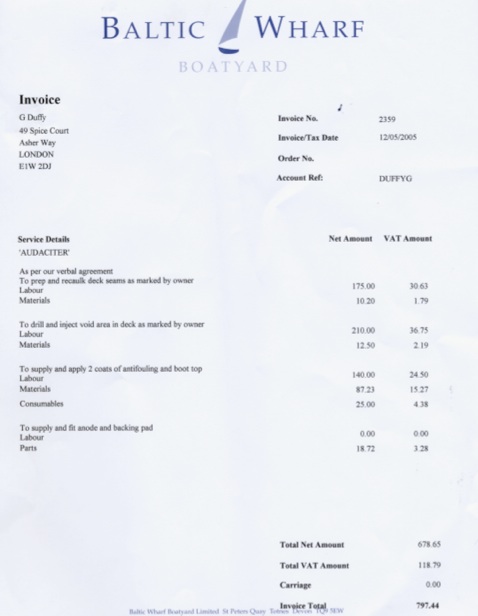

In addition to the hull treatment, Baltic Wharf undertook a few other pieces of work identified on the survey, such as repairing some of the Sikaflex beading and filling small voids in the deck with epoxy.

Below are details of the work undertaken, taken from the quotation and invoices.

Hull epoxy

28 Feb 2005

To prevent the development of Osmosis, Audaciter was taken to a leading UK boatyard to have her hull professionally stripped, dried and epoxied.

dfkl;ads j